Green hydrogen production cost

Current green hydrogen production costs are too high for many companies to widely adopt the use of this greenhouse-gas-free molecule. The problem is that the method commonly used to create green hydrogen involves high levels of renewable electricity being run through an electrolyzer. The cost of the electrolysis equipment and the electricity are simply higher than what gray hydrogen consumers are currently paying.

Level setting with the cost of gray hydrogen

Some argue that companies need to accept they will have to pay more for clean hydrogen. Many expect government policy makers to add multipliers to steam-methane reforming (SMR) hydrogen to level the playing field. But at this point that is merely conjecture. While prices fluctuate, the cost of the gray stuff, derived directly from fossil energy sources, was just over $1 per kg in the United States at the time this page was published. Adding carbon capture and utilization (CCUS) to the equation added another $0.60 or so per kg. So for practical purposes, we will assume somewhere around $2 per kg. Hydrogen can be more like $5 or $6 per kg in Europe, Asia, and Australia. Without government influence or clear directives from policy makers on what incentives or burdens they may apply on either side of the equation, most hydrogen consumers are stuck in a wait-and-see holding pattern. After all, if they make a decision based on expectations of tax breaks or carbon multipliers that never materialize, they could lose millions of dollars over the next few decades. Asset owners and operators simply cannot underwrite this risk.

The tipping point

Again, markets fluctuate all the time. But when this page was authored, the cost of electrolysis-generated green hydrogen at one facility in Spain was 8.93 EUR, or a bit over $9 US. At best, that is a 30-percent increase in cost for hydrogen versus gray for customers who want it. And while some government entities and other consumers can afford to pay a premium, many simply cannot. With expectations of the cost of green hydrogen going down over time, producers hope to deliver a kg of the clean stuff for around $1.50 in the United States within a decade. But 10 years is a long time. And it’s time we don’t have if we are going to reach net zero carbon emissions by 2050.

Where practicality meets reality

The good news is that totally green hydrogen isn’t the only option for moving away from gray/black hydrogen toward net-zero carbon emissions. The key is to deliver the lowest carbon-intensity molecules as close as possible to the point of need (reducing infrastructure and transport costs) at the lowest possible cost.

The Syzygy shock

Syzygy Plasmonics has developed new technology that uses light instead of heat from the combustion of fossil fuels to create hydrogen. This Zero-Emission Hydrogen Photoreactor is undergoing field trials with full commercialization expected sometime in 2023. The feedstock is ammonia and the outputs are hydrogen and nitrogen.

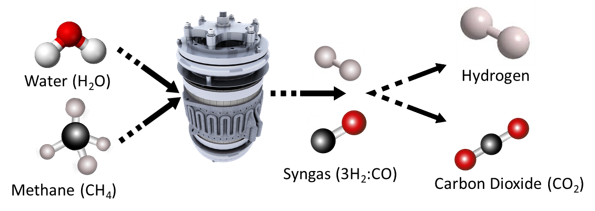

Shortly thereafter we plan to release our Low-Emission Hydrogen Photoreactor . The feedstocks are methane and water and the output is syngas. Given expected electricity use, cost of methane, and photoreactor costs, we expect early adopters to be able to sell 1 kg of zero-emission hydrogen for around $1.50 starting in 2023 or 2024. That’s half a decade ahead of the most optimistic green hydrogen projections for price equity.